Description

NT7®

Technical Terms:

NT7® is a surface treatment for steel and metal alloys that combines sub-micron particles of PTFE (polytetrafluoroethylene), otherwise known as Teflon, with electroless nickel. The application of NT7® is auto-catalytic or electroless. This process is preferable to standard electrolytic plating as all active surfaces are plated with uniform thickness, which is crucial when working with firearms.

Coating thickness can be maintained to within .00001″ or one ten thousandths of one inch, guaranteeing consistent quality coatings. With the PTFE evenly distributed and locked into the nickel-phosphorus matrix, NT7® is a true composite. If wear occurs, fresh particles of PTFE are exposed to keep the opposing surfaces lubricated throughout the life of the coating, which produces a true dry film self-lubricating finish.

Gun Guy Terms:

NT7® will adhere to aluminum, steel, and stainless steel. NT7® is Electroless Nickel with embedded TEFLON®. The TEFLON® is bonded to the particles of Nickel at the molecular level providing self lubrication throughout the entire coating. The Nickel in this finish provides corrosion and abrasion resistance. NT7® is a soft metallic gray color, somewhat similar to bead-blasted stainless steel or titanium.

- NT7 has a micro hardness of 48-55 Rockwell as plated (nickel matrix).

- NT7 has a coefficient of friction as low as .07-.1 according to test standards LFW-1 and ASTM D-2714

- NT7 has PTFE also known as Teflon® co-deposited in the nickel matrix. As wear occurs new PTFE particles are exposed and the self lubricating properties continue.

- NT7 is easy to clean for the same reason that a pan with Teflon® is easy to clean. Teflon® is non-stick and easy to wipe down, therefore carbon does not adhere to the surface.

- NT7 Permits firing for longer periods of time between cleaning, as dirt and powder residue has no wet or oily surface to cling to.

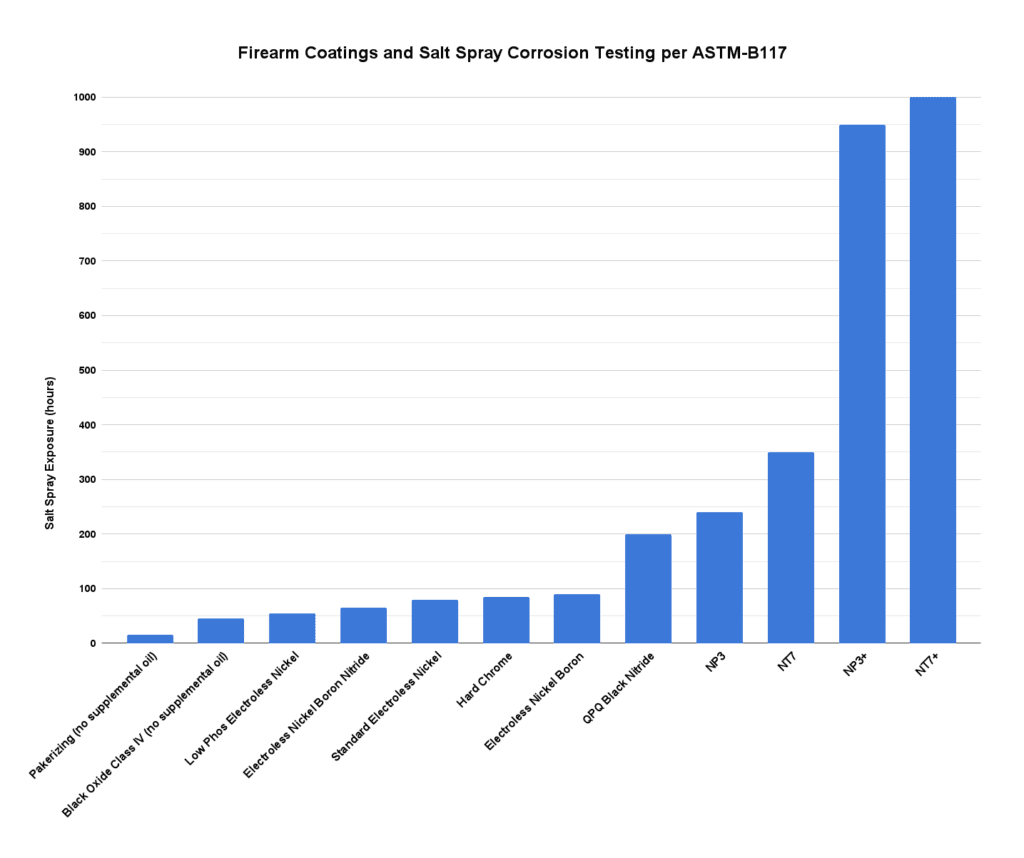

- NT7 has great corrosion resistance, a 1 mil (.001) coating exceeding a 750 hour salt spray test. 3 times that of Nickel Boron.

- NT7 is self lubricating so lubrication is needed on opposing surfaces.

- NT7 has a high lubricity and low friction co-efficient; therefore, the life expectancy of a firearm will be greatly increased due to reduced friction wear.

- NT7 plated onto stainless steel guns will prevent galling, a problem common with stainless steel.

- NT7 is a satin gray, non-reflective color ideal for all firearms.

- NT7 can be plated to all internal parts giving a smoothness to the action not found with any other coating.

- NT7 is guaranteed against coating defects for the lifetime of the firearm.

- NT7 is the last finish you will ever need.

NT7 cannot be applied to Titanium, Scandium or ‘pot metal’. Previously plated surfaces like nickel, hard chrome or anodizing must be stripped prior to plating.

NT7® Plus

NT7+® is a surface treatment for steel and metal alloys that combines sub-micron particles of PTFE (polytetrafluoroethylene), otherwise known as Teflon, with electroless nickel.

NT7®+ has all of the advantages of the the original NT7® listed above as well as almost 4x the Corrosion Resistance of the Standard NT7® coating.

- NT7+ has a micro hardness of 48-55 Rockwell as plated (nickel matrix).

- NT7+ has a coefficient of friction as low as .07-.1 according to test standards LFW-1 and ASTM D-2714

- NT7+ has PTFE also known as Teflon® co-deposited in the nickel matrix. As wear occurs new PTFE particles are exposed and the self lubricating properties continue.

- NT7+ is easy to clean for the same reason that a pan with Teflon® is easy to clean. Teflon® is non-stick and easy to wipe down, therefore carbon does not adhere to the surface.

- NT7+ Permits firing for longer periods of time between cleaning, as dirt and powder residue has no wet or oily surface to cling to.

- NT7+ has great corrosion resistance, a 1 mil (.001) coating exceeding a 1000 hour salt spray test. 10x that of Nickel Boron.

- NT7+ removes the need for lubrication on opposing surfaces.

- NT7+ has a high lubricity and low friction co-efficient; therefore, the life expectancy of a firearm will be greatly increased due to reduced friction wear.

- NT7+ plated onto stainless steel guns will prevent galling, a problem common with stainless steel.

- NT7+ is a satin gray, non-reflective color ideal for all firearms.

- NT7+ can be plated to all internal parts giving a smoothness to the action not found with any other coating.

- NT7+ is guaranteed against coating defects for the lifetime of the firearm.

- NT7+ is the last finish you will ever need.

Reviews

There are no reviews yet.