NT7® & Metal Finishing

We are now accepting orders for NT7 & NT7+

Estimated Lead Times (as of 3/5/2024)

Stripped Parts: 6-8 weeks (for orders that are received as stripped parts in a clean condition)

Assembled Parts: 10-12 weeks (for all orders that require disassembly, gunsmithing, or fitting)

Actual lead times will vary based on backlog.

Please include an order form with your shipment.

NT7 Press Release 5/5/2023

In October of 2021, without any warning the NP3 family of coatings was discontinued from the retail market. We were just as shocked as you and we vowed that we would find a suitable replacement. Our goal was to find a coating that was similar in performance, chemical makeup, and corrosion resistance. Over the past 2 years we have enlisted the help of the top chemical engineers, process engineers, and coating specialists from across the country to help us with this tall order.

Construction of our inhouse plating facility started in March of this year and barring any unforeseen construction delays will be completed by the end of August.

We will be equipped to process: Steel, Stainless Steel, and Aluminum parts. We plan to be processing customer parts starting early August.

The replacement coatings NT7™ & NT7 Plus™ will have very similar performance specs to the NP3 specs and just like their predecessors the “Plus” coating will have a higher corrosion resistance. NT7™ and NT7 Plus™ are based on a Nickel Teflon coating so they will have a similar satin Nickel appearance and the same low coefficient of friction and non-stick properties that we have all come to know and love over the years. We will be releasing pricing and more details about NT7™ as September approaches.

Key Info:

- NP3 has been replaced with NT7™

- NT7™ & NT7 Plus™ will be applied inhouse in our brand new plating facility

- Construction on our inhouse plating facility will be completed 9/1/2023

- We will release pricing and more spec’s for NT7™ & NT7 Plus™ in the coming months

We look forward to better serving you and your firearm refinishing needs in the very near future!

**We are now accepting orders for NT7 and NT7+**

Please include an order form with your shipment.

NT7®

Technical Terms:

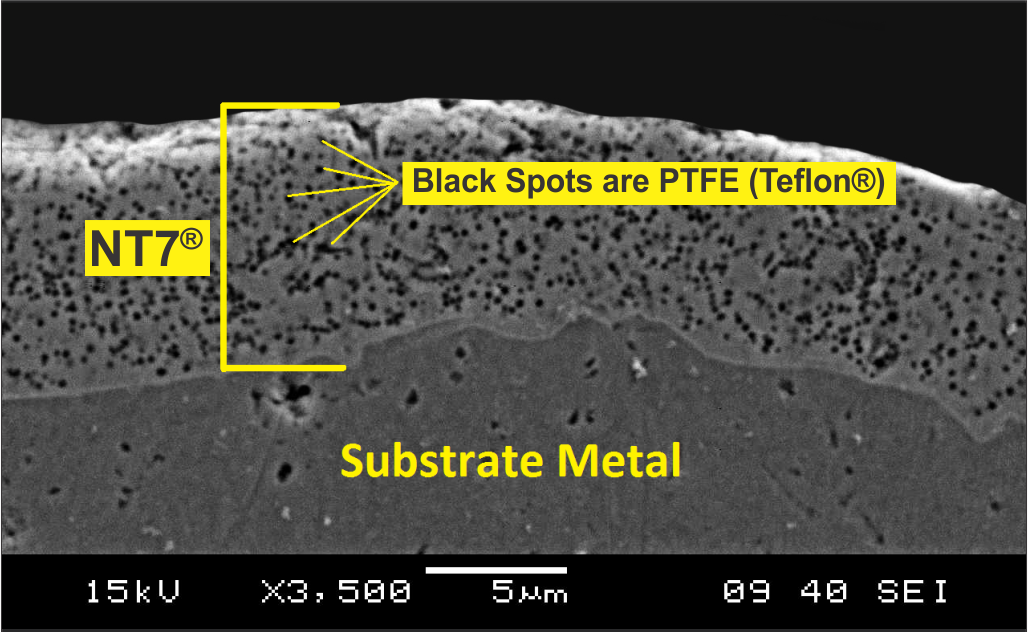

NT7® is a surface treatment for steel and metal alloys that combines sub-micron particles of PTFE (polytetrafluoroethylene), otherwise known as Teflon, with electroless nickel. The application of NT7® is auto-catalytic or electroless. This process is preferable to standard electrolytic plating as all active surfaces are plated with uniform thickness, which is crucial when working with firearms.

Coating thickness can be maintained to within .00001″ or one ten thousandths of one inch, guaranteeing consistent quality coatings. With the PTFE evenly distributed and locked into the nickel-phosphorus matrix, NT7® is a true composite. If wear occurs, fresh particles of PTFE are exposed to keep the opposing surfaces lubricated throughout the life of the coating, which produces a true dry film self-lubricating finish.

Gun Guy Terms:

NT7® will adhere to aluminum, steel, and stainless steel. NT7® is Electroless Nickel with embedded TEFLON®. The TEFLON® is bonded to the particles of Nickel at the molecular level providing self lubrication throughout the entire coating. The Nickel in this finish provides corrosion and abrasion resistance. NT7® is a soft metallic gray color, somewhat similar to bead-blasted stainless steel or titanium.

- NT7 has a micro hardness of 48-55 Rockwell as plated (nickel matrix).

- NT7 has a coefficient of friction as low as .07-.1 according to test standards LFW-1 and ASTM D-2714

- NT7 has PTFE also known as Teflon® co-deposited in the nickel matrix. As wear occurs new PTFE particles are exposed and the self lubricating properties continue.

- NT7 is easy to clean for the same reason that a pan with Teflon® is easy to clean. Teflon® is non-stick and easy to wipe down, therefore carbon does not adhere to the surface.

- NT7 Permits firing for longer periods of time between cleaning, as dirt and powder residue has no wet or oily surface to cling to.

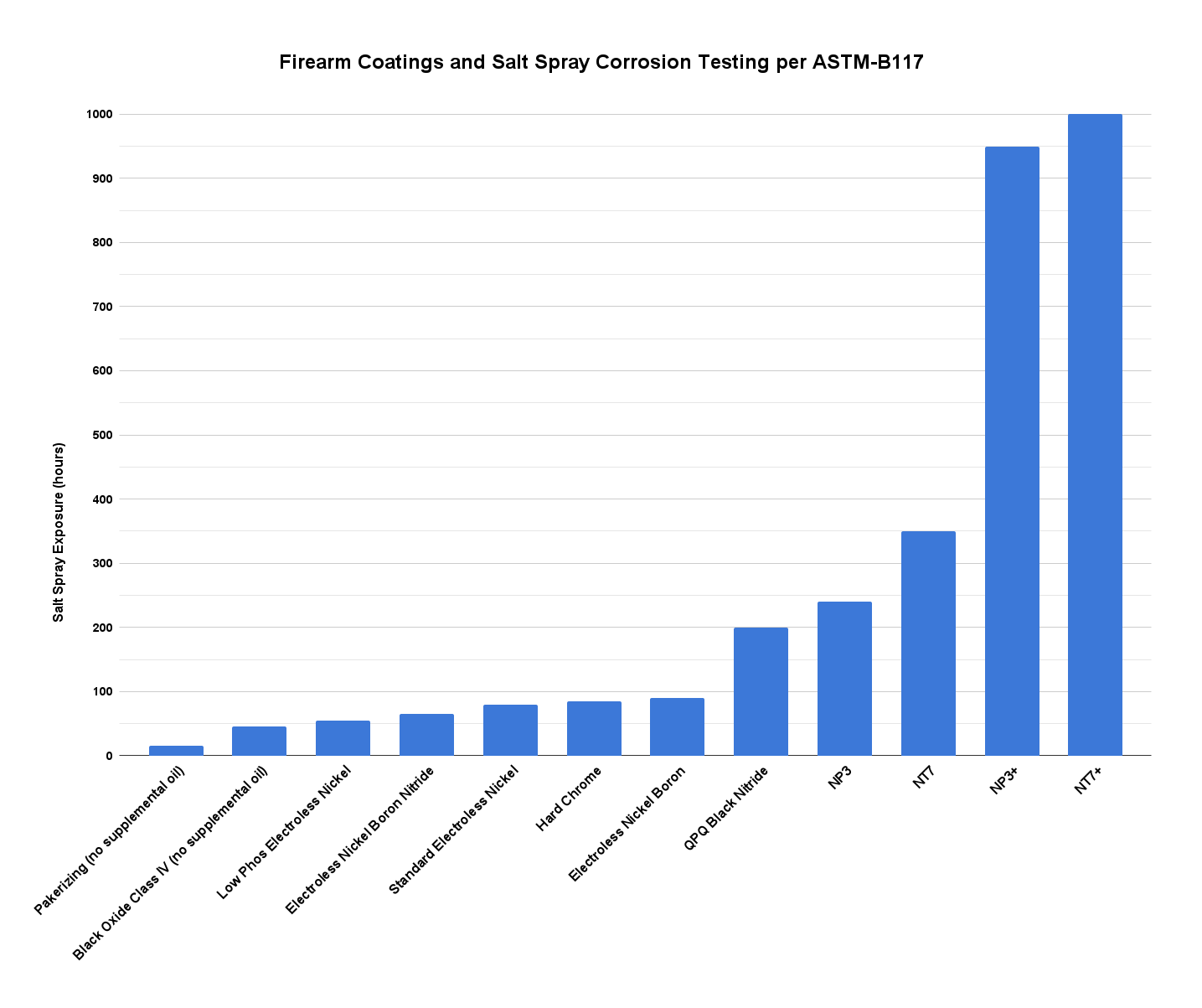

- NT7 has great corrosion resistance, a 1 mil (.001) coating exceeding a 750 hour salt spray test. 3 times that of Nickel Boron.

- NT7 is self lubricating so lubrication is needed on opposing surfaces.

- NT7 has a high lubricity and low friction co-efficient; therefore, the life expectancy of a firearm will be greatly increased due to reduced friction wear.

- NT7 plated onto stainless steel guns will prevent galling, a problem common with stainless steel.

- NT7 is a satin gray, non-reflective color ideal for all firearms.

- NT7 can be plated to all internal parts giving a smoothness to the action not found with any other coating.

- NT7 is guaranteed against coating defects for the lifetime of the firearm.

- NT7 is the last finish you will ever need.

NT7 cannot be applied to Titanium, Scandium or ‘pot metal’. Previously plated surfaces like nickel, hard chrome or anodizing must be stripped prior to plating.

NT7®

NT7® is a surface treatment for steel and metal alloys that combines sub-micron particles of PTFE (polytetrafluoroethylene), otherwise known as Teflon, with electroless nickel.

NT7®+ has all of the advantages of the the original NT7® listed above as well as almost 6x the Corrosion Resistance of the Standard NT7® coating.

- NT7+ has a micro hardness of 48-55 Rockwell as plated (nickel matrix).

- NT7+ has a coefficient of friction as low as .07-.1 according to test standards LFW-1 and ASTM D-2714

- NT7+ has PTFE also known as Teflon® co-deposited in the nickel matrix. As wear occurs new PTFE particles are exposed and the self lubricating properties continue.

- NT7+ is easy to clean for the same reason that a pan with Teflon® is easy to clean. Teflon® is non-stick and easy to wipe down, therefore carbon does not adhere to the surface.

- NT7+ Permits firing for longer periods of time between cleaning, as dirt and powder residue has no wet or oily surface to cling to.

- NT7+ has great corrosion resistance, a 1 mil (.001) coating exceeding a 1000 hour salt spray test. Ten+ times that of Nickel Boron.

- NT7+ removes the need for lubrication on opposing surfaces.

- NT7+ has a high lubricity and low friction co-efficient; therefore, the life expectancy of a firearm will be greatly increased due to reduced friction wear.

- NT7+ plated onto stainless steel guns will prevent galling, a problem common with stainless steel.

- NT7+ is a satin gray, non-reflective color ideal for all firearms.

- NT7+ can be plated to all internal parts giving a smoothness to the action not found with any other coating.

- NT7+ is guaranteed against coating defects for the lifetime of the firearm.

- NT7+ is the last finish you will ever need.

NT7+ cannot be applied to Titanium, Scandium or ‘pot metal’. Previously plated surfaces like nickel, hard chrome or anodizing must be stripped prior to plating.

QPQ Black Nitride

QPQ Black Nitride (Quench Polish Quench) is the next evolution of metal treatment in the firearms industry. QPQ Black Nitride is a surface treatment for Steel and Stainless Steel.

QPQ Black Nitride differs from traditional firearms finishes such as Bluing or Black Oxide as it is not actually a finish on the surface of the part. QPQ Black Nitride is a surface treatment process that improves the performance of the base metal by hardening and polishing it which yields an extremely attractive satin black texture that is virtually bullet proof.

QPQ Black Nitride has replaced our offering for traditional Bluing and Black Oxide finishes. QPQ Black Nitride has a very similar appearance to a standard black oxide finish, but that is where the similarities end. Its is significantly more abrasion resistant and has 5x the corrosion resistance of black oxide.

- 200+ hours of corrosion resistance (NSS)

- Non reflective satin matte black finish

- Extreme wear resistance making it the ideal coating for barrels and slides on duty / carry guns

- Excellent choice for protecting and extending barrel and bore life

Please include an order form with your shipment.

Get In Touch

If you have questions about a potential project or you would like more information about our services, please shoot us an email and we will do our best to get you the info that you need. We look forward to working with you!

info@wrightarmory.com

Mesa Location (Headquarters)

Address: 250 S Mulberry #102 Mesa, AZ 85202

Major Cross Streets: Broadway & Alma School

Phone: 480-550-0965

Email: info@wrightarmory.com

Hours of Operation: Mon-Fri: 10am – 6pm

Tempe Location (Inside C2 Tactical Shooting Range)

Address: 8475 S Emerald Dr #108 Tempe, AZ 85284

Major Cross Streets: I-10 & Warner

Phone: 480-550-0965

Email: info@wrightarmory.com

Hours of Operation: Tue-Sat: 10am – 6pm